Glossy in mold label for dustbin

Basic information

1.In mold labeling (IML) material: complex glossy (PP)

2.In mold labeling (IML) thickness: 65-70 microns

3.In mold labeling (IML) design colors: depend on artwork, normally CMYK+PANTONE colors....

4.In mold labeling (IML) required design file: AI,DWG or PDF format

5.In mold labeling (IML) printing way: by using gravure printing

6.In mold labeling (IML) printing ink: environment friendly ink

7.In mold labeling (IML) dimensions: depend on your 3D mold size

8.In mold labeling (IML) die-cut plate:according to final trial testing before making mass production

Why choose us

1. We have a professional sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique products.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success !

2. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

3. We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

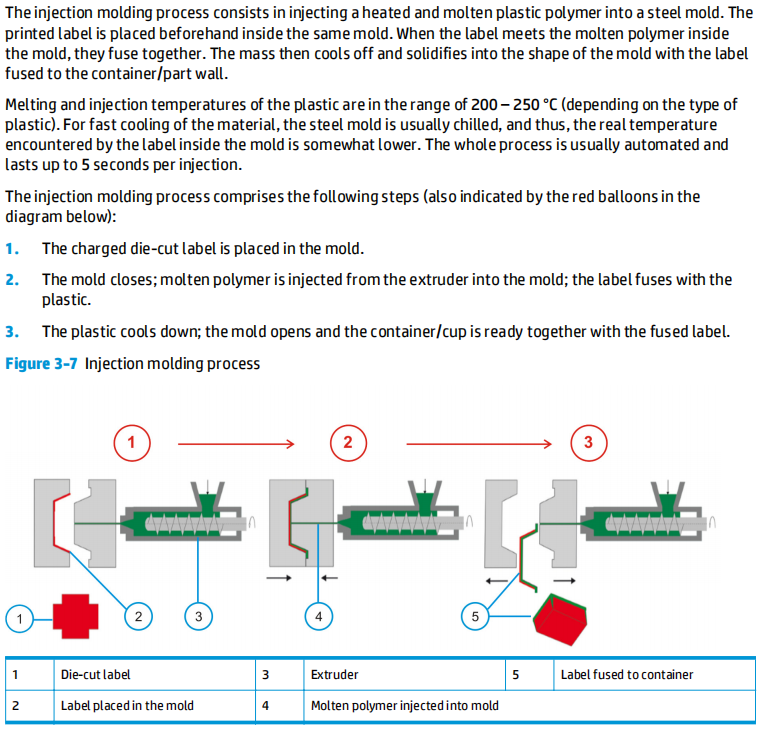

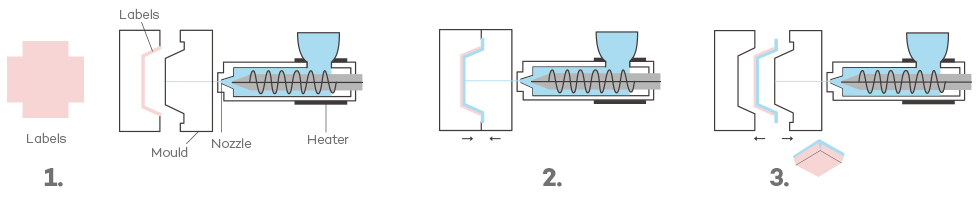

How does in-mold-lable work?

IML injection means that the decoration of the product takes place in the mold. A pre-printed label is first inserted into the mold and fixed in place through application of vacuum or static electricity charge. Then during the manufacturing process, a certain amount of heated liquld molten polymer is injected under high pressure into a mold and fuses with the label. At the end, we get a decorated packaging in one step.

Production Process

Shipment

Application

This complex glossy in mold label is widely used in various kind of food package field such as : juice drink cup ,milk cup ,coffee cup, butter container, ice cream container and outdoor furniture industry and household industry and other industries.

Feature

plastic products with IML can be eco-friendly and fully recyclable, waterproof,oil proof and mildew proof

Faq

Q1:Are you a factory or trading company?

— We are a factory that specialized in making IML more than 10years.

Q2:What's your MOQ?

— 2500 square meters

Q3:Can you supply me samples for free?

— We can supply common sample labels for free ,but if you need your required design sample,it will be charged.

Q4:How to pay the shipping cost of the sample?

— If you have collect EXPRESS account (such as TNT,FEDEX OR DHL) please provide before sending out sample labels

Q5:What’s your delivery time?

— Normally it needs around 7-15 days

Q6:What's your Payment Terms?

— 40% advanced payment and the balance pay before the delivery.